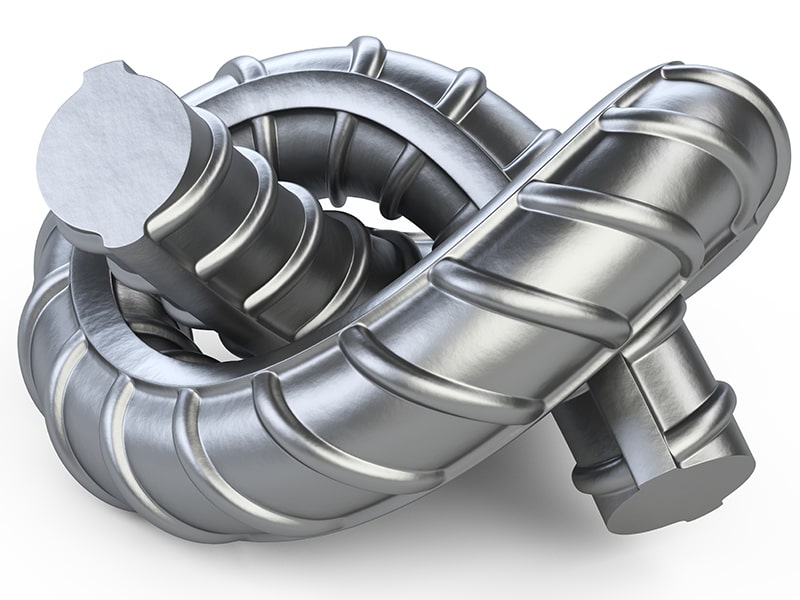

CRS Re-Bars (Corrosion-Resistant TMT Bars)

Built to Endure. Engineered for Tough Environments.

Corrosion is one of the most persistent and damaging threats to reinforced concrete structures. While it may not be entirely preventable, its onset can be significantly delayed through innovation and high-performance materials. Corrosion weakens the embedded steel, compromises structural strength, and leads to costly repairs or premature failure — especially in coastal, humid, or industrial zones.

Why Corrosion Occurs in RCC Structures?

JR Metal’s Innovation in Corrosion-Resistant Steel

After years of dedicated R&D, JR Metal has developed a cost-effective CRS (Corrosion-Resistant Steel) composition specifically engineered to combat corrosion. Our proprietary formulation:

- Significantly slows the rate of corrosion.

- Enhances the lifespan and structural reliability of RCC frameworks.

- Provides added durability in coastal, marine, high-humidity, and chemically exposed areas.

" JR CRS Re-Bars are the smart choice for long-lasting structures, where environmental challenges demand steel that can go the distance."

Standard Sizes and Technical Data

|

Diameter (mm) |

Area (cm2) |

Weight (kg/m) |

Nominal Length (m/MT Approx.) |

Diameter (mm) |

|---|---|---|---|---|

| 6 | 0.28 | 0.206 | 0.222 | 4500 |

| 8 | 0.51 | 0.381 | 0.400 | 2500 |

| 10 | 0.76 | 0.581 | 0.600 | 1670 |

| 12 | 1.11 | 0.854 | 0.872 | 1150 |

| 16 | 1.95 | 1.500 | 1.530 | 650 |

| 20 | 3.07 | 2.393 | 2.410 | 415 |

| 25 | 4.90 | 3.750 | 3.850 | 260 |

Chemical Composition

| Elements | Min (%) | Max (%) |

|---|---|---|

| Carbon | 0.18 | 0.22 |

| Manganese | 0.45 | 0.55 |

| Sulphur | 0.030 | 0.050 |

| Phosphorus | 0.040 | 0.070 |

| Chromium | 0.25 | 0.40 |

| Copper | 0.30 | 0.40 |

| Silicon | 0.15 | 0.25 |

Mechanical Properties

| Property | Fe-415 | Fe-500 |

|---|---|---|

| Yield/0.2% Proof Strength | 415 N/mm² | 500 N/mm² |

| Ultimate Tensile Strength | Ensures a minimum of 10% above the measured yield or proof strength, with an absolute minimum not less than 485 N/mm². | Ensures a minimum of 8% above the measured yield or proof strength, with an absolute minimum not less than 545 N/mm². |

| Elongation (5d gauge length) | Min 14.5% | Min 12% |

| Bend Test | Successfully meets bend test requirements by withstanding 180° bending around a mandrel of 3D for diameters up to and including 22 mm, and 4D for diameters above 22 mm. | Successfully meets bend test standards by withstanding 180° bending around a mandrel of 4D for diameters up to and including 22 mm, and 5D for diameters above 22 mm. |

| Re-bend Test | Successfully satisfies re-bend test requirements by bending around a mandrel of 5D for diameters up to and including 10 mm, and 7D for diameters above 10 mm, with a 45° initial bend followed by a 22.5° reverse bend. | |

CRS Manufacturing Process at JR Metal

At JR Metal, our Corrosion-Resistant Steel (CRS) Re-Bars are the result of a carefully engineered metallurgical process designed to strengthen the steel’s resistance to environmental degradation. By adding select alloying elements during manufacturing, we significantly reduce the steel’s susceptibility to corrosion.

Key Alloying Elements in JR CRS Re-Bars

Copper (Cu)

Copper fills the micro-pores that typically form in rust layers, thereby preventing the penetration of oxygen and moisture. This slows down the corrosion process and enhances the bar's durability in moisture-laden environments.

Chromium (Cr)

Chromium improves the passivity of the steel surface, making it less reactive to environmental elements. It enhances pitting resistance and forms an invisible, self-healing protective layer that guards against aggressive corrosion agents like chlorides.

Phosphorus (P)

Phosphorus acts as an anodic inhibitor, disrupting the electrochemical reactions responsible for corrosion. It slows down the corrosion rate, especially in marine and polluted environments, and contributes to the long-term stability of reinforced concrete structures.

" Through this precise chemical composition and controlled manufacturing process, JR CRS TMT Bars offer superior performance in aggressive conditions, delivering reliability, safety, and longevity for critical structures."